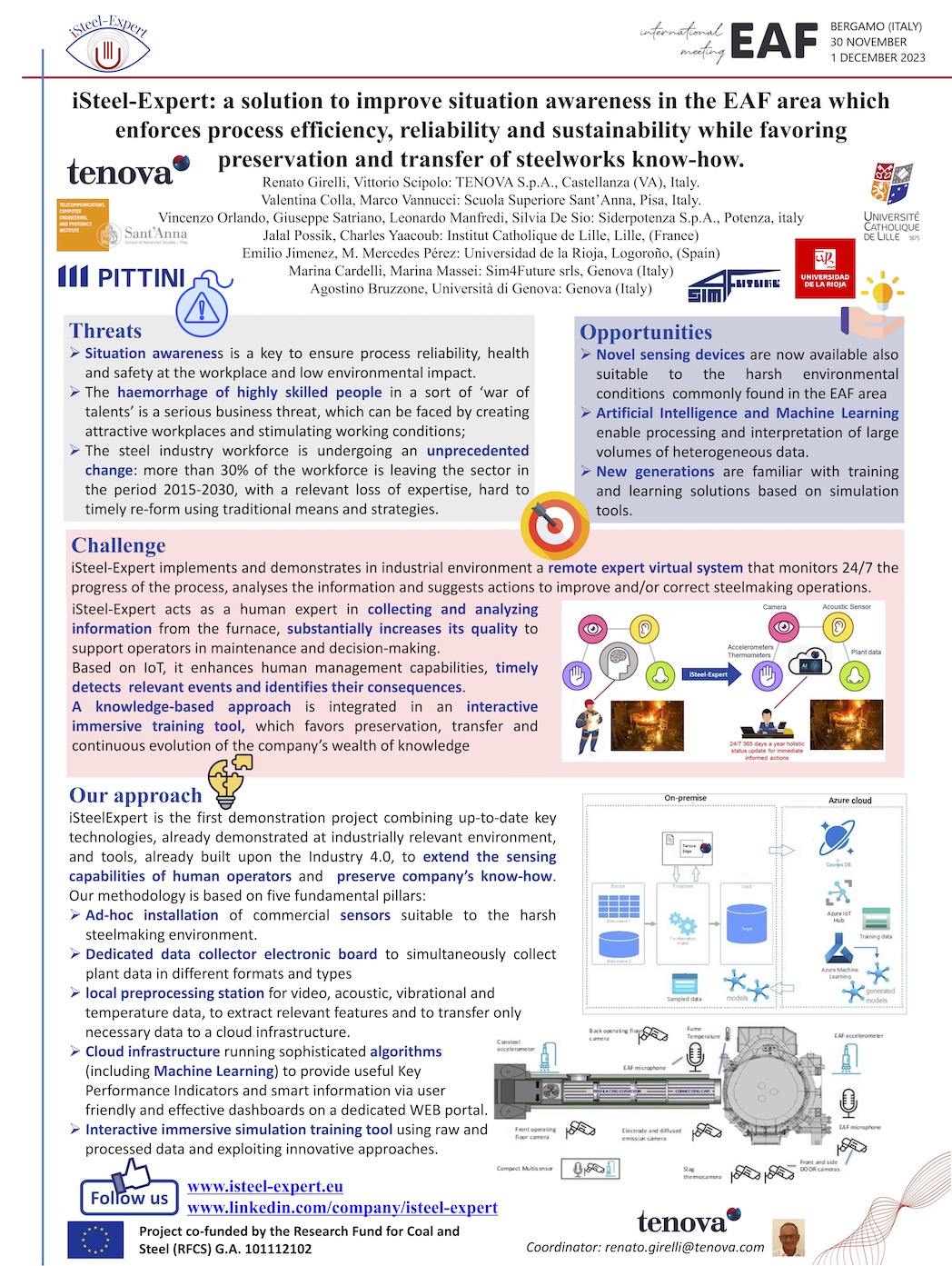

iSteel-Expert: a solution to improve situation awareness in the EAF area which enforces process efficiency, reliability and sustainability while favouring preservation and transfer of steelworks know-how.

iSteel-Expert: a solution to improve situation awareness in the EAF area which enforces process efficiency, reliability and sustainability while favouring preservation and transfer of steelworks know-how.

AUTHORS:

Renato Girelli, Vittorio Scipolo: TENOVA S.p.A., Castellanza (VA), Italy.

Valentina Colla, Marco Vannucci: Scuola Superiore Sant’Anna, Pisa, Italy.

Vincenzo Orlando, Giuseppe Satriano, Leonardo Manfredi, Silvia De Sio: Siderpotenza S.p.A., Potenza, Italy.

Jalal Possik, Charles Yaacoub: Institut Catholique de Lille, Lille, France.

Emilio Jimenez, M. Mercedes Pérez: Universidad de la Rioja, Logoroño, Spain.

Marina Cardelli, Marina Massei: Sim4Future srls, Genova Italy.

Agostino Bruzzone:

Università di Genova Genova Italy.

Important challenges in the transformation of the European steel industry come from social phenomena that are potentially destructive for the business continuity:

Decision support systems jointly exploirng multiple sensing devices, that provide very heterogeneous data and approaches for continuous operators’ know-how inclusion and preservation, are uncommon in steelworks and so far, not exploited in the EAF monitoring and management.

In such a context, the EU-funded research project entitled “Remote expert virtual system enhancing human management capabilities and favors preservation, transfer and continuous evolution of knowledge for steelmaking operations” (iSteel-Expert, G.A. No. 101112102) has been launched in July 2023.

iSteel-Expert aims at modernizing the EAF area by implementing a novel integrated approach based on virtual system able to monitor events and suggest improvements based on a Machine Learning-based pre- analysis of gathered data. The iSteel-Expert system based on IoT, will act as a human expert supporting standard and maintenance operations and will enhance human management capabilities, by detecting relevant events and their consequences. Finally, it will implement a knowledge-based approach that working integrated in an interactive immersive training tool, will favor preservation, transfer and continuous evolution of steelwork’s wealth of knowledge.”

The structure of the project and the approach to use enabling digital technologies, for to improving workforce management, health, and safety in the EAF area, as well as energy efficiency increase and GHG emission reduction, will be presented.

Project co-funded by the Research Fund for Coal and Steel

Project co-funded by the Research Fund for Coal and Steel